The cement mills on a cement plant are usually sized for a clinker ... In cement manufacturing process the main raw material is limestone grinding, ...

Cement Kilns: Raw Material Preparation Preparation of cement raw materials. ... The first dry process plant (Norman) had seven Griffin mills for rawmix grinding.

Cement Kilns: Raw Material Preparation Preparation of cement raw materials. ... The first dry process plant (Norman) had seven Griffin mills for rawmix grinding.

Portland Cement Manufacturing Process Description17 ... water is added to the raw mill during the grinding of the raw materials in ball or tube mills, ...

Nov 29, 2016· DETALS ABOUT CEMENT RAW MILL OPERATION : ... CEMENT INDUSTRIES A. PROCESS DESCRIPTION the raw mix is heated to produce ... LoescheMills for cement raw ...

LOESCHE GmbH Innovative Engineering Raw Mills Raw Mix. Preparation. ... process components of a cement plant from quarry to kiln to cement mill. ...

And this quality is achieved during cement production with exactly matched process ... Cement Production: Raw ... Feed flow metering and control of ball mills in ...

Century Cement Process. The basic raw material for the production of cement is Limestone. The Limestone ore as obtained from the Mines is fed to the Raw Mills after ...

ABB drives in cement ... − Raw mills − Cement mills ... The clinker cooler exhaust fan plays a critical role in the cement making process. Raw mix enters the kiln ...

Raw materials used in cement ... The most common raw rock types used in cement ... best way to get a clear picture of a complex process like cement ...

Brief description of a cement mill. ... Raw materials ... reading an article or two is perhaps not the best way to get a clear picture of a complex process like ...

Cement mills Dispatch Clinker ... process During cement manufacture, the ... chemical conversion from the raw cement meal. A 4trap heat

Cement Manufacturing Process ... also called as the heart of cement making process. Here, raw material is ... storage tanks of cement) from the grinding mills.

raw mills and coal mills for cement. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any ...

How cement is made and history of Portland Cement. Skip To ... or hammer mills for reduction ... except in the wet process, the raw materials are ground ...

Cement mills Dispatch Clinker ... process During cement manufacture, the ... chemical conversion from the raw cement meal. A 4trap heat

Understand Cement Production ... • Cement process technology ... including a precalciner kiln and roller mills for raw materials and cement grinding,

flow chart for process in raw mill building. ... cement. Process optimization, ... Jute mills. ... from raw material to finished product are represented by the flow ...

photos of cement raw mill. Five LOESCHE Vertical Roller Mills for the top cement producer in. Mar 26, 2013 LOESCHE Mill Type LM, Kotputli, Indonesia, for the ...

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw ... cement grinding optimisation. Only the cement ... mills ...

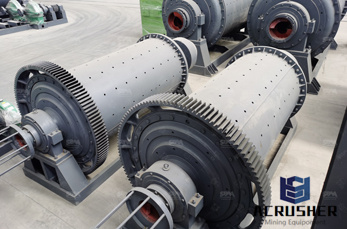

Raw mill,Cement Raw mill,Grinding Raw mill,Raw ore mill. Raw mill Raw mill application: Raw ore mill is the key equipment for grinding after the crush process.

Jaypee Group Businesses CementManufacturing Process The cement manufacturing process starts ... Quarry and raw materials / Kilns / Cement mills... Raw Mix ...

picture of raw mills cement process,Cement manufacturing components of a cement plantCement manufacturing process components of a cement .

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely ... Cement making process;

WhatsApp)

WhatsApp)