Cement Process Energy Saving. Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier eye, Figure 1 Cement Production Process Dry Powder Mixer ...

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

Cement: Materials and manufacturing process. construction procedure from raw mill to cement mill in cement. Chemically, cement is a mixture of calcium silicates and ...

The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill Open and Close circuit

2014 Top Quality Ball Mill For Hematite,Iron Ore,Copper Ore, such as cement, silicate, new building material, refractory material, ferrous metal, nonfer ball mill.

Cement Plant Operations Handbook ... Cement Milling 69 1. ... Physical Test – 13. Process Control Analysis – 14. Cement Strength – 15.

effects of grinding media shapes on ball mill. Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries.

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan ... Cement mill Admix mill Cement Silo Mixer Weigher Shipping Bulk loader Packer

A nonlinear learning control approach for a cement milling process milling process cement,In this paper, a novel parameter tuning strategy for a class of ...

Optimizing the Control System of Cement Milling: Process Modeling and Controller Tuning Based on Loop Shaping Procedures 157 Brazilian Journal of Chemical ...

Cement Milling. Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media ...

Cement grinding Vertical roller mills versus ball ... • the feed to a cement mill is ... Dehydration of the gypsum added to the cement In the grinding process ...

The clinker is taken from the clinker storage to cement ball mill hoppers for cement grinding. and slag for slag ... Manufacturing process < All about Cement ...

Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan ... Cement mill Admix mill Cement Silo .

Brief description of a cement mill. Understanding ... reading an article or two is perhaps not the best way to get a clear picture of a complex process like cement ...

A cement mill (or finish mill in ... and roll presses are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill .

feed mill flow chart – grinder – CGM Supply the aggregate . BLOCK DIAGRAM FOR CEMENT, the ball mill has two feed,flow chart of raw . raw mill process ppt ...

The cement mill. Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating ...

procedure of cement mill errection standard operating procedure for crushing what is the procedure for crushing strength of concr standard operation procedure .

erection procedure of cement mill YouTube. Apr 17, 2016 ... erection procedure of cement mill. xiaotian bai ... How to Cover a Concrete Wall with Stone Veneer ...

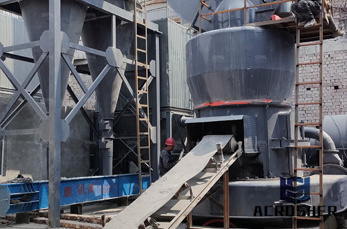

Advanced process control for the cement industry ... provides advanced process control and optimization for cement plants, ... Vertical Roller Mill Application

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

WhatsApp)

WhatsApp)